Ender 3 - Bert: Difference between revisions

Jump to navigation

Jump to search

JohnTauchus (talk | contribs) |

No edit summary |

||

| (16 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

=== Bert is a Creality Ender 3 (upgraded) === | === Bert is a Creality Ender 3 (upgraded) === | ||

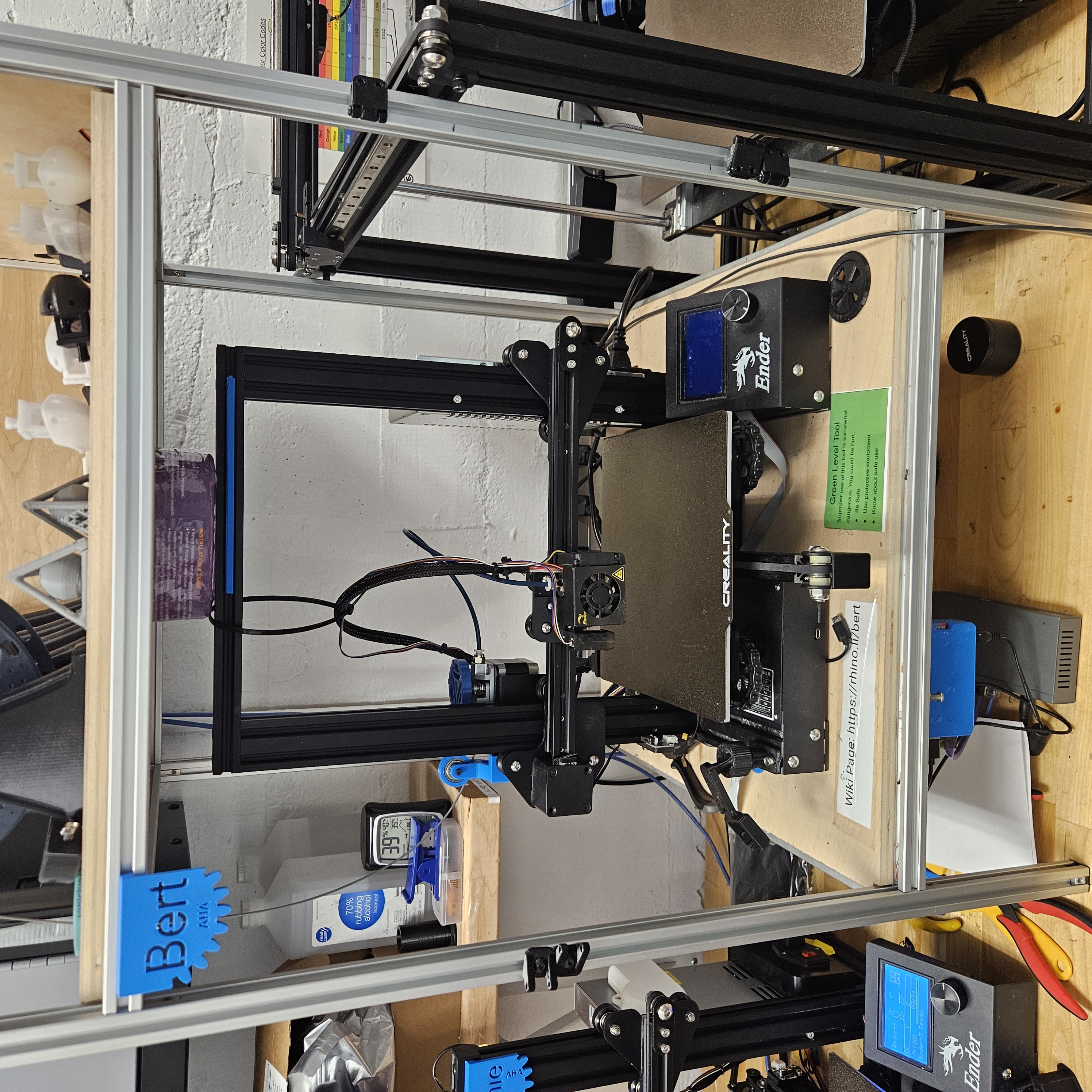

[[File:2025-04-24 17.52.24.jpg|thumb|Bert, an Ender 3]] | |||

== Summary == | == Summary == | ||

| Line 7: | Line 8: | ||

You might need to do the steps below for yourself or someone remote asking if anyone in the space can setup the printer. | You might need to do the steps below for yourself or someone remote asking if anyone in the space can setup the printer. | ||

* '''Clearing a print''' | * '''Clearing a print''' Simply wait until the build plate is cool, remove it from the magnetic surface on the carriage, and flex it '''lightly''' to pop off your print. Please don't use glue or metal scrapers of any kind on the flexible metal sheet. The plastic "razor blade" (not an ''actual'' razor blade) scraper is acceptable to use to remove any remaining stuck material. | ||

Loading and unloading filament | Loading and unloading filament | ||

* | * PLA should melt well at 215C, PETG at 245C. You can use the LCD controls, or the temperature tab in the printer's Octoprint page to heat the nozzle before loading the filament. Do not force it in if it's not feeding smoothly. '''NOTE:''' If you are loading PLA: keep in mind that the previous user might have had PETG in the machine, which means you need to heat up to PETG temperature to purge the nozzle effectively. Once the nozzle is purged of any PETG, you should turn down the temperature ASAP to avoid scorching your PLA. You might want to purge a little extra PLA just in case. | ||

=== Absolute slicing settings === | === Absolute slicing settings === | ||

| Line 24: | Line 22: | ||

Filament dia.: 1.75mm | Filament dia.: 1.75mm | ||

Feel free to download the PrusaSlicer [https://drive.google.com/file/d/1Zhm7Tp6lw52BYIUGcNb1cHELllZ14UlL/view?usp=sharing printer profile] for use on your own computer. | |||

=== Variable Slicing Settings === | === Variable Slicing Settings === | ||

All other slicing settings depend on material and aspects of the part. The table below contains the latest tested slicing profiles and is only considered a starting point. Consult your software manuals on how to import these profiles. A good source of information for all the variable settings can be [https://all3dp.com/2/slic3r-ender-3-profile-settings/ found here]. | All other slicing settings depend on material and aspects of the part. The table below contains the latest tested slicing profiles and is only considered a starting point. Consult your software manuals on how to import these profiles. A good source of information for all the variable settings can be [https://all3dp.com/2/slic3r-ender-3-profile-settings/ found here] and [https://all3dp.com/2/prusaslicer-ender-3-best-profile/ here]. | ||

{| class="wikitable" | {| class="wikitable" | ||

|+ | |+ | ||

| Line 35: | Line 35: | ||

|- | |- | ||

|PrusaSlicer | |PrusaSlicer | ||

| | |Works with nearly-default Ender 3 settings | ||

| | | | ||

| | | | ||

| Line 53: | Line 53: | ||

==== Octoprint access when you are on the internal space Member Wifi ==== | ==== Octoprint access when you are on the internal space Member Wifi ==== | ||

login | login URL: https://10.255.225.70 | ||

URL: | |||

User: AHAender3 | User: AHAender3 | ||

| Line 60: | Line 59: | ||

Pass: TheNextGeneration | Pass: TheNextGeneration | ||

[[Category:3D Printers]] | |||

[[Category:Tools]] | |||

Latest revision as of 19:47, 22 September 2025

Bert is a Creality Ender 3 (upgraded)

Summary

Basic before and after printer setup.

You might need to do the steps below for yourself or someone remote asking if anyone in the space can setup the printer.

- Clearing a print Simply wait until the build plate is cool, remove it from the magnetic surface on the carriage, and flex it lightly to pop off your print. Please don't use glue or metal scrapers of any kind on the flexible metal sheet. The plastic "razor blade" (not an actual razor blade) scraper is acceptable to use to remove any remaining stuck material.

Loading and unloading filament

- PLA should melt well at 215C, PETG at 245C. You can use the LCD controls, or the temperature tab in the printer's Octoprint page to heat the nozzle before loading the filament. Do not force it in if it's not feeding smoothly. NOTE: If you are loading PLA: keep in mind that the previous user might have had PETG in the machine, which means you need to heat up to PETG temperature to purge the nozzle effectively. Once the nozzle is purged of any PETG, you should turn down the temperature ASAP to avoid scorching your PLA. You might want to purge a little extra PLA just in case.

Absolute slicing settings

Bed size: 220x220

Print Height: 250

Nozzle size: .4mm

Filament dia.: 1.75mm

Feel free to download the PrusaSlicer printer profile for use on your own computer.

Variable Slicing Settings

All other slicing settings depend on material and aspects of the part. The table below contains the latest tested slicing profiles and is only considered a starting point. Consult your software manuals on how to import these profiles. A good source of information for all the variable settings can be found here and here.

| PLA | PETG | ABS | |

|---|---|---|---|

| PrusaSlicer | Works with nearly-default Ender 3 settings | ||

| Cura | |||

| Simplify3D | PLA |

Printing With Octoprint

Octoprint access when you are on the internal space Member Wifi

login URL: https://10.255.225.70

User: AHAender3

Pass: TheNextGeneration