Projects

This is a dump of all projects that people have expressed interest in working on!

Space Improvements

Inventory

- SDS collection

- Need/Have list

- Whereis map

Safety Regulation Compliance

- Inspect the space to be sure we're complying with the following known safety standards::

- General safety standards:

- First aid kits are up to date and properly labeled

- Food and beverage stations (fridges, counters, appliances, etc) are equipped with sanitation equipment (solution bucket, tablets, cloths, pH strips)

- Michigan Rights & Safety posters are hung up and clearly visible

- Clutter is kept free of of work benches, tools, and walkways

- Chemical safety standards:

- All chemicals are in appropriate, undamaged, sealable, properly labeled containers

- All chemicals have an associated Safety Data Sheet that is easily located

- All chemicals (when not in use) are put away in lockable cabinets, or cabinets out of reach of visitors (adults or minors)

- Combustible chemicals are kept in a separate Flammables Cabinet

- Fire safety standards:

- Fire extinguishers are up to date and properly mounted

- All exits are clearly labeled, unobstructed, and escape route maps are hung up and clearly visible

- Breaker boxes are properly labeled

- Safe distances are clearly marked in yellow and black tape around all breaker boxes

- Tool safety standards:

- Safe distances are clearly marked in yellow and black tape around all standing tools

- All standing tools have one copy of the user manual safely attached to the tool in a plastic bag and clearly visible

- A copy of the user manual for all power tools in the space is available and easy to find (in the library or a filing cabinet)

- All tools requiring certification are clearly and visibly labeled as such

- All power tools are currently in good working order with all safety guards and guides in place and well-maintained

- Broken tools that are waiting to be repaired are clearly and visibly labeled as such

- Broken tools that cannot be repaired have been disposed of safely

- All hand tools and small power tools are safely put away when not in use

- All tool accessories are stored with the tool they match, if safe to do so, or are properly labeled and stored away

- PPE safety standards:

- Proper ear protection is available and clearly visible

- Proper eye protection is available and clearly visible

- Proper respiratory protection is available and clearly visible

- Proper, latex-free skin protection is available and clearly visible

- Alcohol wipes for ear, eye, and mask sanitation are available, safely stored, and easily accessible

- General safety standards:

- Determine what additional standards we are required to comply with

Backing up Production Computers

- Ideally: A simple method for doing as close to a bare metal backup as possible of the primary production machines at AHA, ie:

- Scotty (CNC/Laser/3D Printing machine in Proto room)

- AHA-Central (Windows 7 Ultimate: Shift machine behind desk)

- All Hands Active (Windows 7 Ultimate: Main machine in primary AHA Workspace)

- AHA-Mega (Ubuntu Box: Label Printer Machine on side work bench in AHA Workspace)

- Once a month should be often enough to get most of the general / major changes covered

- Having one or two USB Bootable Clonezilla drives for plugging in, booting up, and one or two steps for a general user to activate backup.

- Testing to make super backup implementation is just as simple

- Centralizing where production files (ie: Personal .gcode, .stl, etc.) go, and having those backed up online more often would be nice

(see imaging PCs for update)

- Raises the question of whether or not people want their files being uploaded onto the internet.

- Raises the question of what sort of privacy people can expect with their files.

Exploration: Imaging PCs

1/20/2013 - Front Door/Entrance way.

- A-Frame sign: Needs printing, laminating and mounting. Needs: Print laminate and mount.

- Main Ops sign on building: Josh measured and had a new filler piece created. Needs a piece of acrylic lasercut (makerworks or i3?) and vinyl or paint applied to make the sing Needs: Lasercutting, vinyl/paint, mount.

- DogFort

- Window holes need work, talk to Josh. Sizes of remaining holes: 6 x 3.5, 1 x 3.75, 1 x 4, 4 x 7, 2 x 7.25, 2 x 7.5 (num holes * inches diameter for each hole). Rule of thumb: cut acrylic half an inch smaller. Cut cardstock ring up half an inch for outer and half to 3/4 of an inch inner.

Member Projects

Backyard Brains Projects

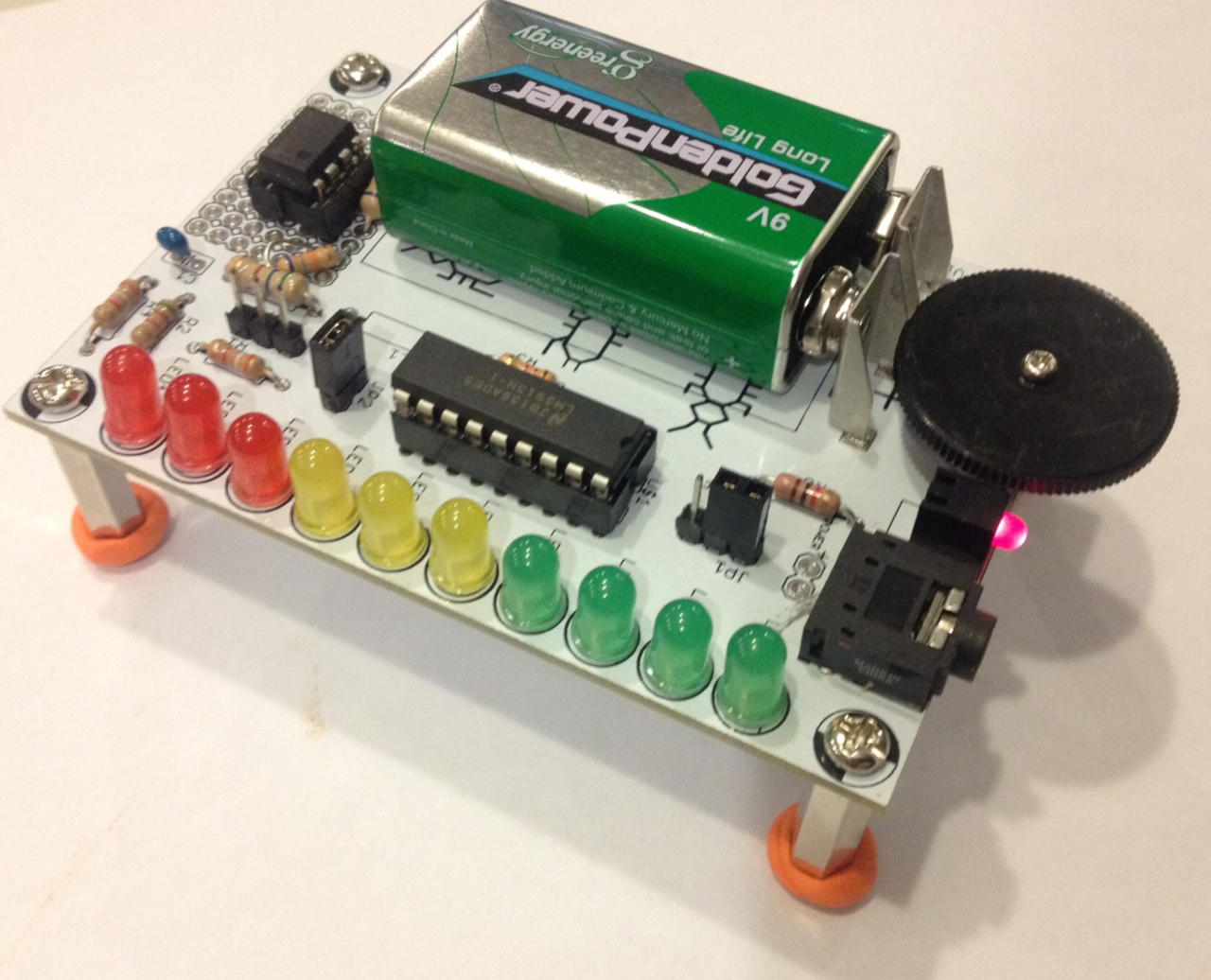

LED Neural Encoder

We are trying to build a DIY device to convert an analog spike or muscle activity signal into an LED bar graph so students can easily see the amount of activity and quantify it. We have some prototype boards. But we still need some help. Let me know if you are interested in helping! Contact: Greg Gage

Bluetooth RoboRoach

If you are not familiar with the RoboRoach, it is the world's first commercially available cyborg (half machine - half cockroach). And it was made right here in Ann Arbor. We used to hack a HexBug to make this work, but recently updated this to use a Bluetooth Chip. It worked, but its too fancy. It's Bluetooth 4.0, which only works on the iPhone 4s. We want to make a Bluetooth 2.1 version using the Arduino, or some other PIC. Want to help? Contact: Greg Gage

DIY SMT Soldering Oven

We want to use a toaster oven, an Arduino, and a temperature sensor to allow us to do Reflow Soldering. Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to tack down tiny chips. Once heated up, the solder paste melts and creates an electrical connection between the chip and the pads. This invention would be really useful for hackerscpaces around the world. Contact: Greg Gage

Big 3D Printer

This will be a longer-term project involving the construction of a Rostock delta-like 3D printer; should give us a lot more speed and precision, along with a much larger printing area, and it should be easier to maintain if something breaks. We've got most of the parts on order. Get in contact with one of the folks below if you would like to help!

Contacts: Michael Sh., Tyler W., Nate Y.

Currently in a working state. Excellent for events where we need a reliable project that's interactive and engaging.

Here are some people to poke if you have questions about the Scanmera:

Xander H. Jenn M. Josh W. Nate Y.

Estes E2X Equivalent

- Project Page: E2X Equivalent

- Lead: Josh W.

- 12 Pack of Easy to Assemble Rockets costs $66 from Estes, that's $5.50 p/student

- Can we make similar, or equivalent pieces with a 3D Printer?

- What is the time to print?

- What is the cost of materials?

- Does it hold up?

- If all goes well, what possibilities are there for custom built pieces for more unique rockets?

Back room temperature / humidity network sensor

- Lead: Ed V.

- Project Page: not yet

- Raspberry Pi + sensor shield or components to measure temp, humidity, other interesting things in back room

- Usefulness! If temp is wrong or humidity is wrong can't be used for plastics molding